Introduction

New statistical process control (SPC) methods have to be developed in order to handle more and more complex data, which are available because of the advent of new data acquisition technologies. In particular, in many practical situations the quality characteristic of a process can be modelled as a function defined on a compact domain, data of such kind are the foundation of a rapidly expanding area of statistics referred to as functional data analysis (FDA). SPC methods which allow monitoring and controlling such processes are known as profile monitoring techniques. As in the classical SPC (i.e., where data are scalars) profile monitoring control charts have the task of continuously monitoring the quality characteristic and of triggering a signal when assignable sources of variations (i.e., special causes) act on it. When this happens, the process is said to be out-of-control (OC). On the contrary, the process is said to be in-control (IC) when only normal sources of variation (i.e., common causes) apply.

Often, measures of other functional covariates related to the quality

characteristic are available. To this end, we propose a new control

chart that continuously monitors the quality characteristic using

information coming from the other functional covariates. The idea is to

adjust the quality characteristic value in order to improve the accuracy

and the effectiveness of the chart in identifying assignable sources of

variations acting on the process. This chart is referred to as

functional regression control chart (FRCC) due to the similarity to

the regression control chart, which arises in the multivariate (non

functional) context. The proposed methodology is implemented in the R

package funcharts available at

https://github.com/unina-sfere/funcharts.

The Functional Regression Control Chart Framework

The FRCC can be regarded as a general framework for profile monitoring

that can be divided into three main steps. Firstly, (i) define a

functional regression model to be fitted $$\label{eq_generalmodel}

\tilde{Y}=g\left(\mathbf{\tilde{X}}\right)+\varepsilon,$$ where

$\tilde{Y}$ is the functional response variable, which represents the

functional quality characteristic, and $\varepsilon$ is a functional

error term, both defined on the compact domain $\mathcal{T}$, $g$ is a

generic function of a vector $\mathbf{\tilde{X}}$ of random functional

covariates $\tilde{X}_1,\dots,\tilde{X}_p$, defined on the compact

domain $\mathcal{S}$. Secondly, (ii) define the estimation method of the

chosen model, and, thirdly (iii) define the monitoring strategy of the

functional residual defined as $$\label{eq_generalresiduals}

\tilde{e}=\tilde{Y}-\widehat{\tilde{Y}} ,$$ where $\widehat{\tilde{Y}}$

is the fitted value of $\tilde{Y}$.

In particular, to obtain a specific implementation of the FRCC, we

assume that the covariates $\mathbf{X}$ linearly influence the response

$Y$ through the multivariate functional linear regression model, that

is $$\label{eq_lm}

Y\left(t\right)=\int_{\mathcal{S}}\left(\mathbf{\beta}\left(s,t\right)\right)^{T}\mathbf{X}\left(s\right)ds+\varepsilon\left(t\right)\quad t \in \mathcal{T},$$

where $Y$ and $\mathbf{X}$ are the standardized versions of $\tilde{Y}$ and

$\tilde{\mathbf{X}}$, and

$\mathbf{\beta}=\left(\beta_1,\dots,\beta_p\right)^{T}$ is the coefficient

vector. An estimator $\hat{\mathbf{\beta}}$ of the coefficient vector

$\mathbf{\beta}$ is obtained using $n$ i.i.d. observations of the response

and predictor variables, and considering the multivariate functional principal component or

Karhunen–Loève decomposition of $Y$ and

$\mathbf{X}$. To monitor the residual $\tilde e$, we consider the Hotelling’s $T^{2}$

and the squared prediction error ($SPE$) control charts based on the

scores of the functional principal component decomposition. The control

limits are calculated using percentiles of the empirical distributions

of the two statistics, estimated considering observations acquired under

in-control conditions and an overall Type I error. This phase, along

with the estimation of $\mathbf{\beta}$, will be

referred to as Phase I. For a new observation, the residual and, thus,

the $T^{2}$ and $SPE$ statistics are calculated and an alarm signal is

issued if at least one statistic violets the control limits (Phase II).

Real-case Study: Fuel Consumption Monitoring in the Shipping Industry

To demonstrate the potential and the applicability of the proposed

control chart in practical situations, a real-case study in the shipping

industry is presented. It addresses the issue of monitoring ship fuel

consumption and, thus, $\text{CO}_{\text{2}}$ emissions, which, in view of the dramatic

climate change, is of great interest in the maritime field in the very

last years. In particular, real data are collected from a Ro-Pax ship

owned by the Italian shipping company Grimaldi Group linking two ports

in the Mediterranean sea from December 2014 to October 2017.

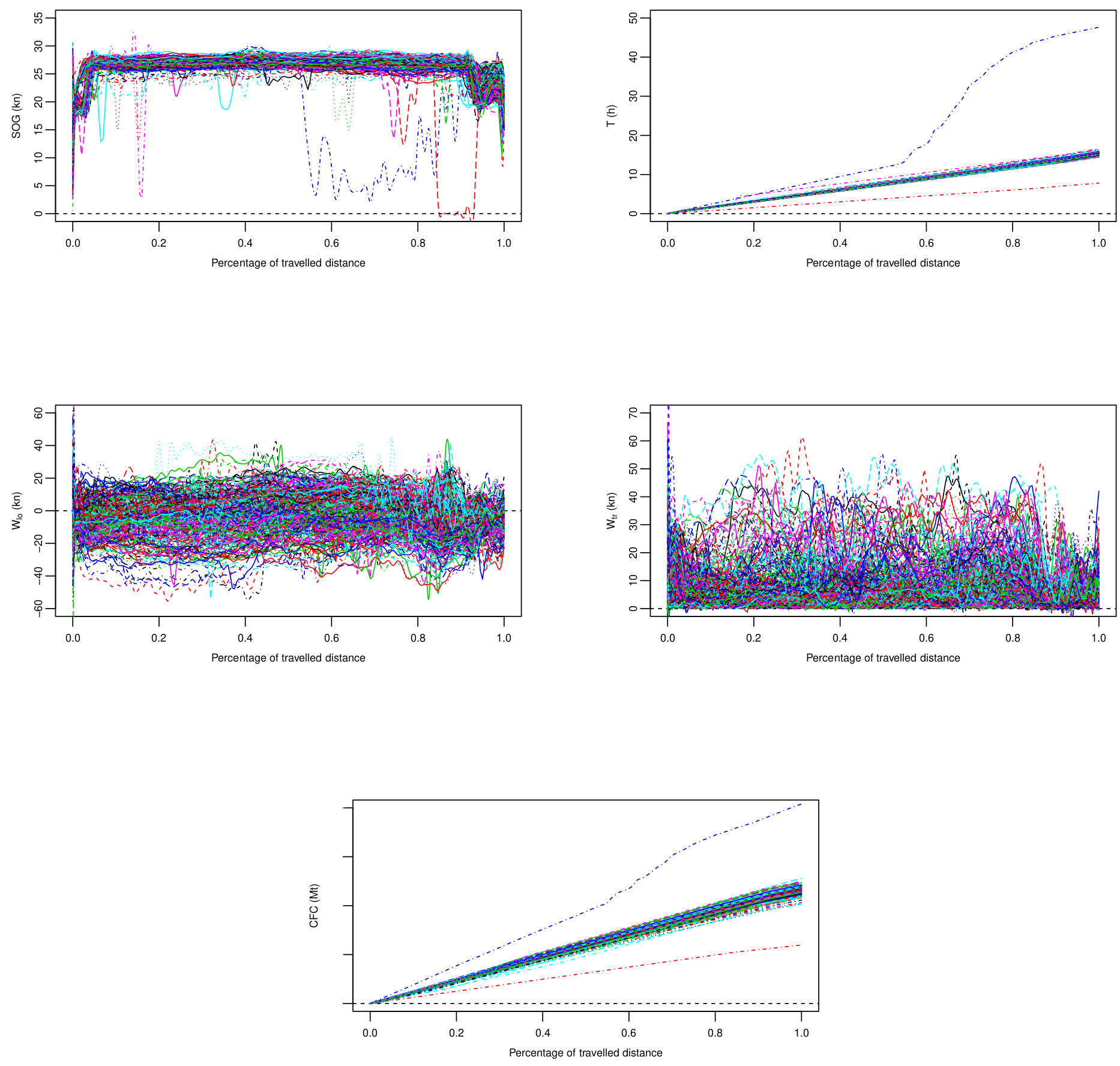

The following figure shows the

315 profiles observed for the covariates and response.

In particular, the cumulative fuel consumption ($CFC$) per each voyage

is considered as the response variable, whereas, the sailing time

($T$), measured in hours ($h$), the speed over ground ($SOG$),

measured in knots ($kn$), and the longitudinal and transverse wind

components ($W_{lo}$ and $W_{tr}$), measured in knots ($kn$), are

assumed as the predictors.

During February 2016 energy efficiency operations were performed that

produced a shift in the response mean. In light of this, observations

before energy efficiency operations are used in Phase I, whereas the

remaining observations are used to perform Phase II. To evaluate the

FRCC performance, two competitor profile monitoring schemes are

considered. They consist of monitoring scores coming from a principal

decomposition of the response by means of Hotelling’s $T^{2}$ and the

$SPE$ control charts (hereafter denoted as RESP control chart), and of

monitoring the area under the response curve (hereafter denoted as INBA

control chart). The performance of the three charts is evaluated by

means of the average run length ($\text{ARL}$).

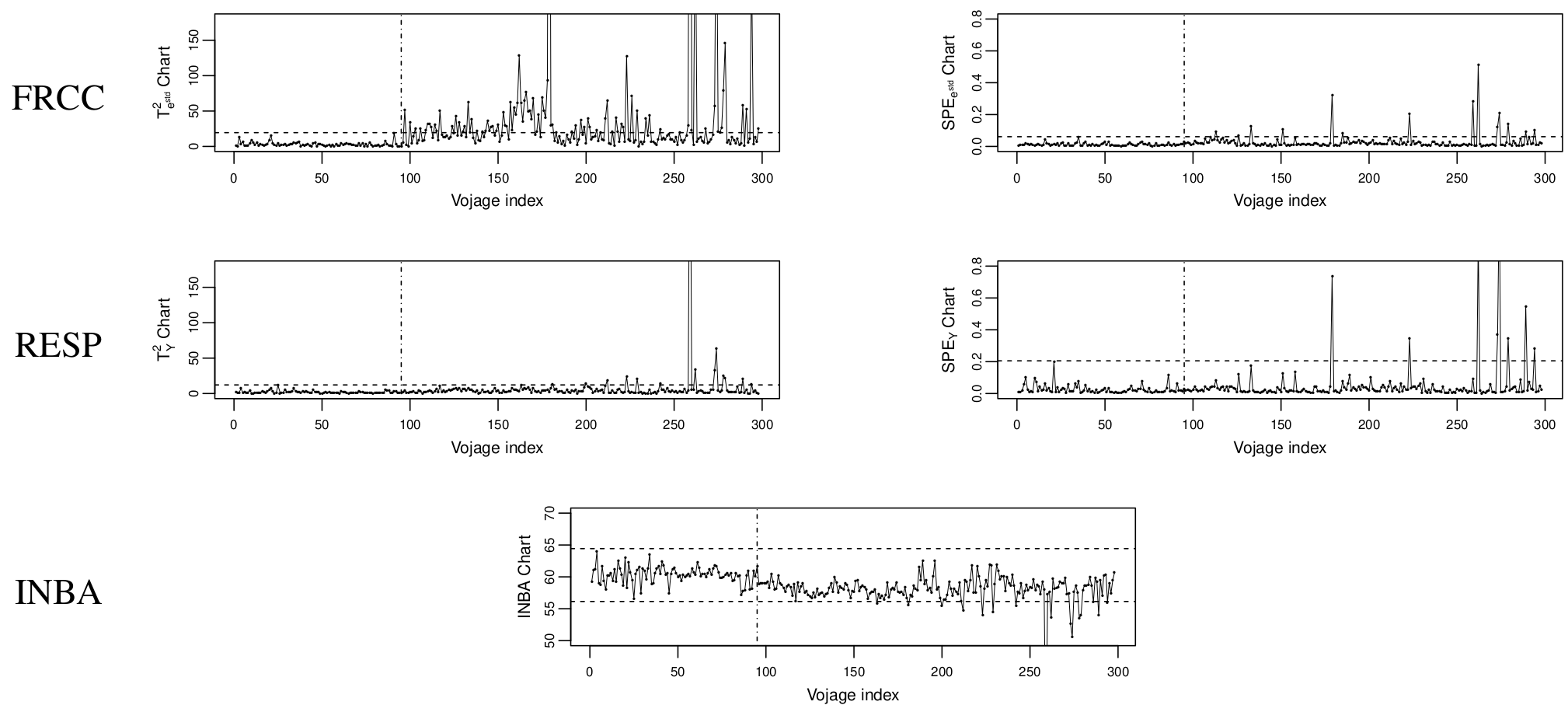

In the following figure, each observation is plotted onto the FRCC control chart and the two competitor ones.

By comparing the three charts, the responsiveness of the FRCC is

evidently higher than that of the the INBA and the RESP control charts

which signal a much lower number of OCs. In particular, for the FRCC the

change in the response mean is almost exclusively captured by the

$T^{2}$ control chart, which means that dissimilarities between the

Phase I and Phase II samples occur mostly in the space spanned by the

retained principal components. Moreover, by looking at the following table,

the estimated $\text{ARL}$ ($\widehat{\text{ARL}}$) achieved by FRCC is at least a

fourth of those achieved by the RESP and INBA control charts. This

further confirms that the FRCC outperforms the competitor control

charts.

| FRCC | RESP | INBA | |

|---|---|---|---|

$\widehat{\text{ARL}}$ |

2.07 | 9.46 | 11.28 |

This article is based on

Centofanti, Fabio, Antonio Lepore, Alessandra Menafoglio, Biagio

Palumbo, and Simone Vantini. "Functional Regression Control Chart."

Technometrics (2020): 1-14, DOI:

https://doi.org/10.1080/00401706.2020.1753581.

Authors’ biography

Fabio Centofanti is a

PhD student at the Department of Industrial Engineering of the

University of Naples Federico II, Italy, fabio.centofanti@unina.it. His research interests include

functional data analysis and statistical process monitoring.

Fabio Centofanti is a

PhD student at the Department of Industrial Engineering of the

University of Naples Federico II, Italy, fabio.centofanti@unina.it. His research interests include

functional data analysis and statistical process monitoring.

Antonio Lepore is an

Assistant Professor at the Department of Industrial Engineering of the

University of Naples Federico II, Italy, antonio.lepore@unina.it. His main research interests

include the industrial application of statistical techniques to the

monitoring of complex measurement profiles from multi-sensor acquisition

systems, with particular attention to renewable energy and harmful

emissions.

Antonio Lepore is an

Assistant Professor at the Department of Industrial Engineering of the

University of Naples Federico II, Italy, antonio.lepore@unina.it. His main research interests

include the industrial application of statistical techniques to the

monitoring of complex measurement profiles from multi-sensor acquisition

systems, with particular attention to renewable energy and harmful

emissions.

Alessandra Menafoglio is an Assistant Professor at MOX, Department of

Mathematics, Politecnico di Milano, alessandra.menafoglio@polimi.it. Her research interests focus on the

development of innovative statistical models and methods for the

analysis and statistical process control of complex observations (e.g.,

curves, images, functional signals), possibly characterized by spatial

dependence.

Alessandra Menafoglio is an Assistant Professor at MOX, Department of

Mathematics, Politecnico di Milano, alessandra.menafoglio@polimi.it. Her research interests focus on the

development of innovative statistical models and methods for the

analysis and statistical process control of complex observations (e.g.,

curves, images, functional signals), possibly characterized by spatial

dependence.

Biagio Palumbo is an

Associate Professor in “Statistics for experimental and technological

research” at the Department of Industrial Engineering of the University

of Naples Federico II, Italy, biagio.palumbo@unina.it. His major research interests include

reliability, design and analysis of experiments, statistical methods for

process monitoring and optimization and data science for technology.

Biagio Palumbo is an

Associate Professor in “Statistics for experimental and technological

research” at the Department of Industrial Engineering of the University

of Naples Federico II, Italy, biagio.palumbo@unina.it. His major research interests include

reliability, design and analysis of experiments, statistical methods for

process monitoring and optimization and data science for technology.

Simone Vantini is

Associate Professor of Statistics at the Politecnico di Milano, Italy, simone.vantini@polimi.it.

He has been publishing widely in Functional and Object-Oriented Data

Analysis. His current research interests include: permutation testing,

nonparametric forecasting, process control, non-Euclidean data, and in

general statistical methods and applications motivated by business or

industrial problems.

Simone Vantini is

Associate Professor of Statistics at the Politecnico di Milano, Italy, simone.vantini@polimi.it.

He has been publishing widely in Functional and Object-Oriented Data

Analysis. His current research interests include: permutation testing,

nonparametric forecasting, process control, non-Euclidean data, and in

general statistical methods and applications motivated by business or

industrial problems.